COATINGS FOR ANY CONDITION

Coatings are applied to “carbon steel” fasteners, heat treated for strength and durability. In addition, SPAX® offers fasteners in 304 stainless steel.

Interior Fastener Coatings

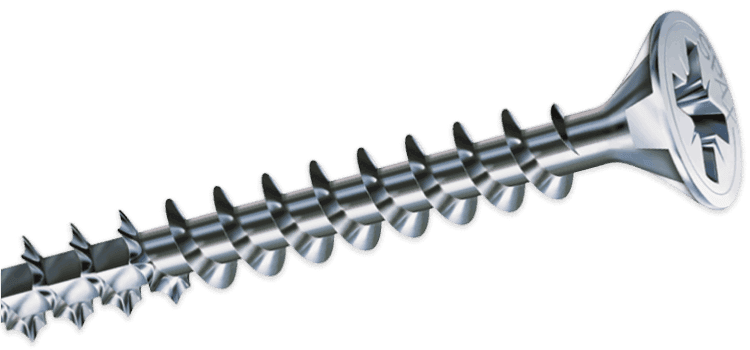

Zinc

“Clear zinc” is tested and recognized for use in untreated and above ground contact pressure treated lumber for interior dry/damp general construction applications.

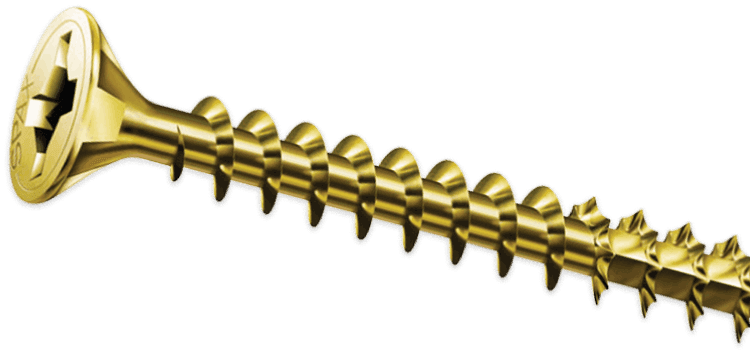

Yellow Zinc

“Yellow zinc” is tested and recognized for use in untreated and above ground contact pressure treated lumber for interior dry/damp general construction applications.

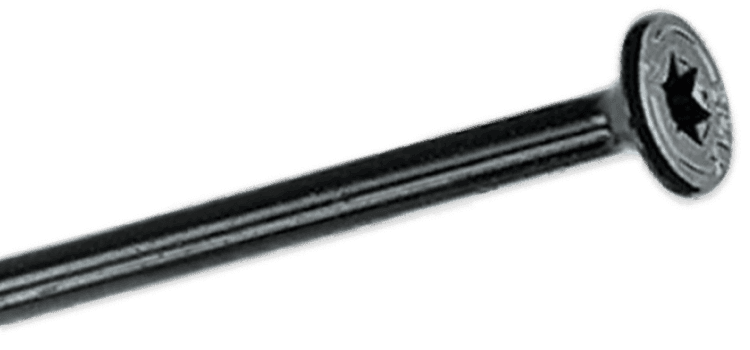

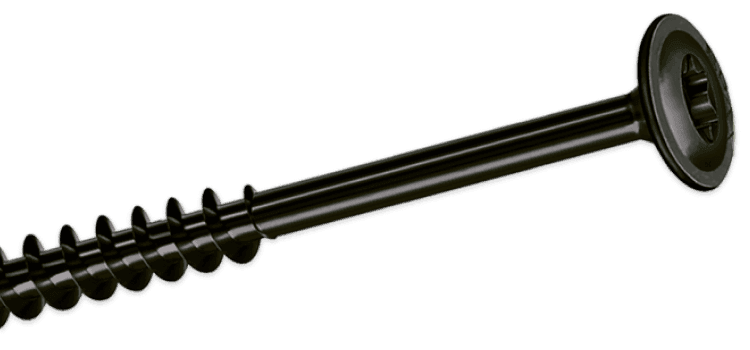

ECoat

“eCoat” is recognized for use in untreated and above ground contact pressure treated lumber for interior dry/damp general construction applications.

WIROX®

“WIROX” is tested and recognized for use in untreated and above ground contact pressure treated lumber for interior dry/damp general construction applications.

Exterior Treated Lumber Approved Fastener Coatings

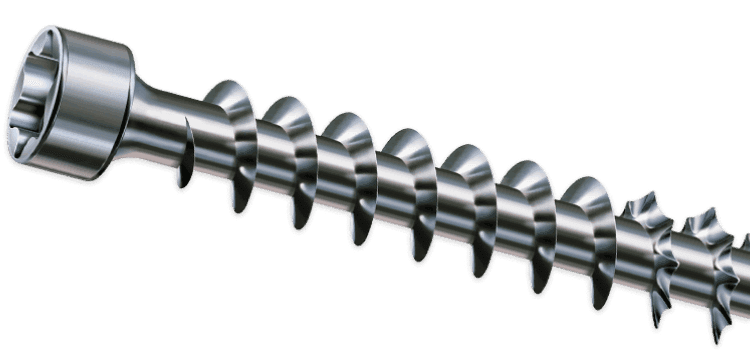

HCR®

HCR is a dual-barrier coating system designed to extend the longevity of SPAX® fasteners in ground-contact, treated lumber and exterior freshwater applications. Plated with a zinc base coat and finished with a durable top coat, they are engineered to withstand the toughest conditions.

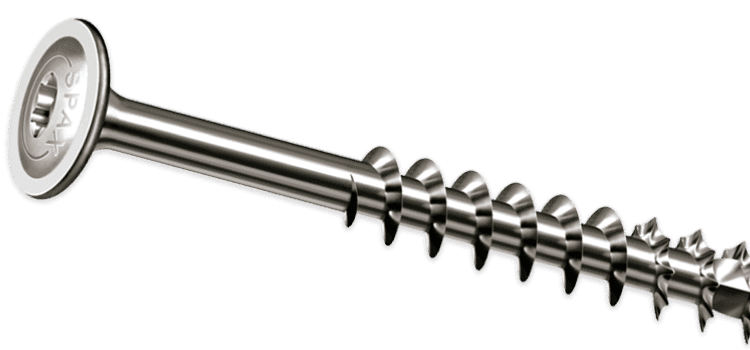

HCR-X™

HCR-X is a SPAX-developed, proprietary, dual- barrier coating system with superior corrosion protection against red rust, designed for use in both treated lumber and freshwater environments.

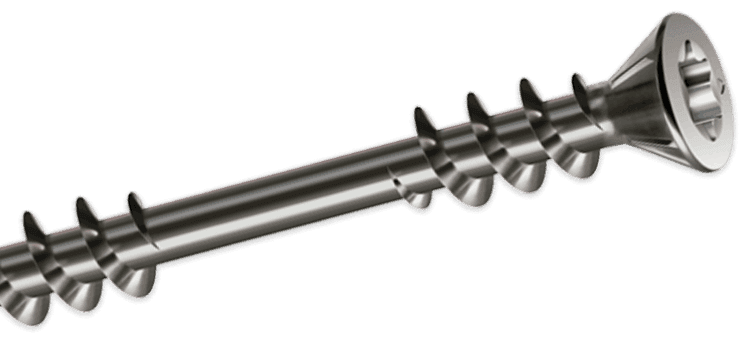

Stainless Steel

304 stainless steel fasteners provide code- compliant use in ground-contact, pressure-treated, and fire-retardant-treated lumber in general and coastal construction projects. They’re well-suited for use with cedar and redwood decking.

AWPA Building Codes

Building code officials are required to have in-depth knowledge of all types of construction methods and thousands of different products used in modern buildings. The International Code Council’s committees recognize AWPA as the authority on treated wood and have directly referenced AWPA Standards in the International Building Code and International Residential Code in applications where preservative treated wood is required.

The Use Categories are a shorthand method of describing the various hazards to which wood products may be exposed. A brief description of the Use Categories is shown.

Information referenced from the AWPA site.

| Use category | Brief description |

|---|---|

| UC1 | Interior Dry |

| UC2 | Interior Wet |

| UC3A | Exterior Above Ground, Coated with Rapid Water Runoff |

| UC3B | Exterior Above Ground, Uncoated or Poor Water Runoff |

| UC4A | Ground Contact, General Use |

| UC4B | Ground Contact, Heavy Duty |

| UC4C | Ground Contact, Extreme Duty |

| UC5A | Marine Use, Northern Water (Salt or Brackish Water) |

| UC5B | Marine Use, Central Water (Salt or Brackish Water) |

| UC5C | Marine Use, Southern Water (Salt or Brackish Water) |

| UCFA | Interior Above Ground Fire Protection |

| UCFB | Exterior Above Ground Fire Protection |

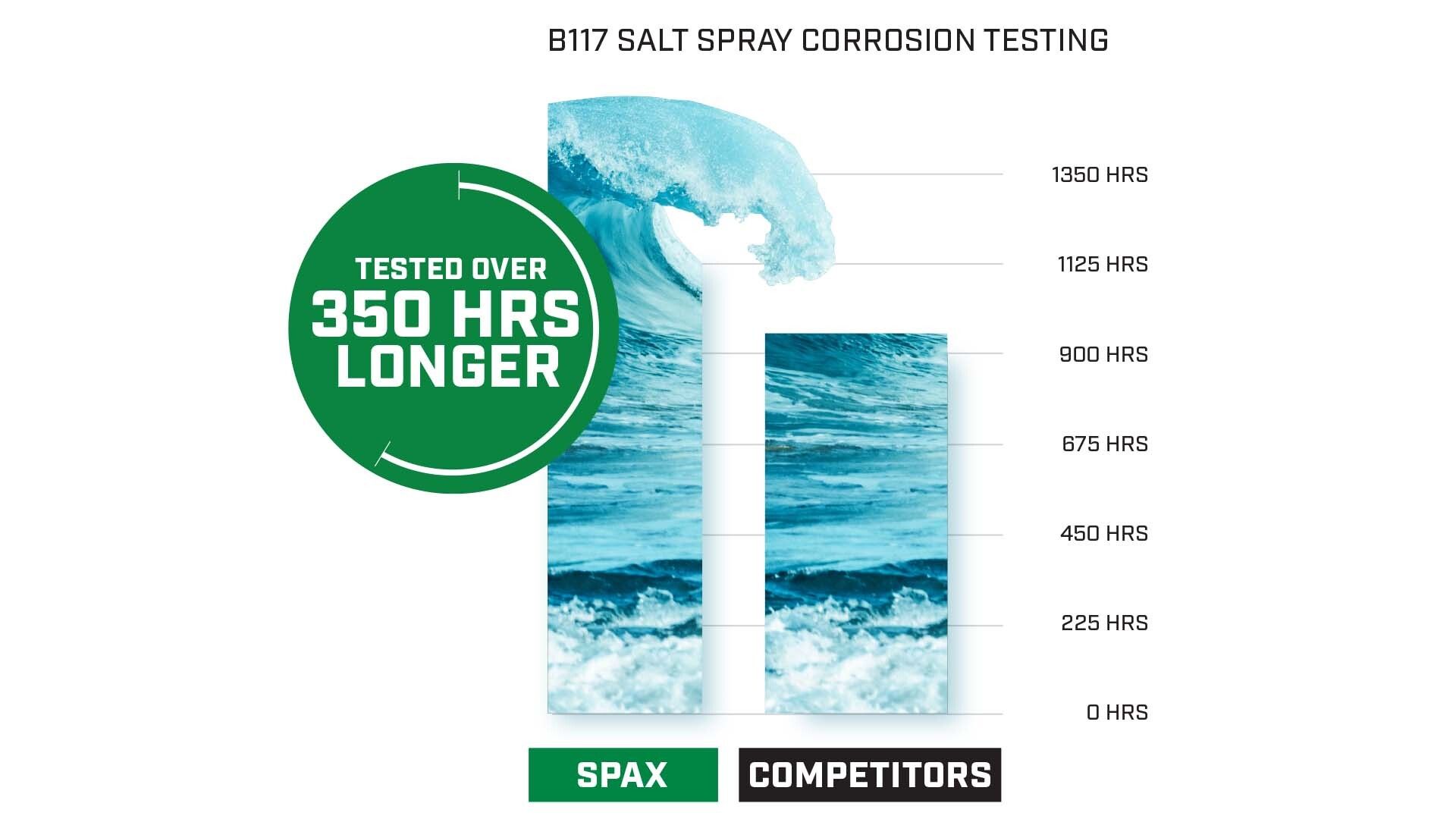

Tested Beyond the Norm

We test and inspect beyond all standards to deliver exceptional structural support—from head to point. Push past what’s expected with time-tested confidence in every connection.

Our Double Barrier Coating

Our HCR® (High Corrosion Resistance) double-barrier coatings offer superior protection with a double barrier. First plated with a zinc base coat and finished with a durable top coat, they’re engineered to hold up to the harshest conditions. Tested and recognized for use in ground contact pressure treated lumber for exterior, freshwater general construction applications (e.g., AWPA UC1-UC4A, UCFA).

DID YOU KNOW?

Some competitors don’t actually test their coatings. They rely on data from their paint company before it makes it onto their screws.