How to Install Furring Strips with SPAX® Fasteners

Accelerate your project with SPAX® fasteners, designed for reliable performance when installing furring strips on concrete, block, or masonry walls. Our screws deliver secure, long-lasting anchoring you can count on.

Master Your Projects with Confidence

SECURELY ATTACH FURRING STRIPS TO CONCRETE, BLOCK, OR MASONRY WALLS

It's important to note that the choice of fastener used when attaching furring strips to concrete and masonry walls will depend on various factors, including the specific requirements of your project, the weight and load-bearing capacity needed, and the type of furring strips and materials being attached. Always follow the manufacturer's guidelines and recommendations when using multi-material fasteners to ensure proper installation and long-term durability.

We’ve Got You Covered

Find the right screw or fastener for your next job with the largest variety of diameters, lengths and head styles in the industry.

Related Products

How to Attach Furring Strips to Concrete or Masonry Walls

Attaching furring strips to concrete or masonry basement walls is a common method used to create a space for insulation and to provide a surface for attaching drywall or other finishing materials. Here are the steps to attach furring strips to concrete or masonry basement walls:

Prepare the materials and tools

Gather the necessary materials, including furring strips (pressure-treated wood or metal), multi-material screws or masonry anchors, a drill, a hammer drill with a masonry bit, a level, a tape measure, a pencil or marker, and safety equipment such as goggles and gloves.

Measure and mark the wall

Use a tape measure to determine the desired spacing for the furring strips. Typically, a spacing of 16 to 24 inches (40 to 60 cm) is used, depending on the size of the wall and the building code requirements. Mark the top and bottom of each furring strip on the wall with a pencil or marker.

Drill pilot holes

With a hammer drill equipped with a masonry bit, drill pilot holes into the concrete or masonry at the marked locations. The pilot holes should follow the fastener manufacturers recommended diameter for use in concrete or masonry.

Install the furring strips

Position the first furring strip against the wall, aligning it with the marked locations. Use a level to ensure it is straight and plumb. Insert a multi-material screw or masonry anchor through the furring strip and into each pilot hole. Use a drill or wrench to tighten the screws or anchors securely. Repeat this process for the remaining furring strips, maintaining the desired spacing.

Check for level and adjust

Periodically check the level of the furring strips as you install them to ensure they are straight and even. Adjust as necessary before securing them in place.

Cut or trim the furring strips

If needed, cut or trim the furring strips to fit around any obstructions, such as electrical outlets or pipes. Use a saw appropriate for the material of the furring strips.

Insulate and finish the wall

Once the furring strips are securely attached, you can install insulation between them. Depending on your preferences and local building codes, you can use foam board insulation, fiberglass batts, or other suitable insulation materials. Finally, install your chosen finishing material, such as drywall or paneling, over the furring strips.

Remember to follow any applicable building codes and safety guidelines during the process. If you're uncertain or uncomfortable with any step, it's always a good idea to consult a professional for assistance.

Optimal rigidity, malleability, and material strength

Proprietary heat treatment process optimizes each fasteners shear strength without breakage.

Why SPAX® Multi-material Screws Are Ideal for Furring Strips on Concrete Walls

When installing furring strips on concrete, masonry, or block walls, using a multi-material fastener like SPAX® reduces hassle and improves hold strength. Here’s why these screws are ideal for your next wall prep project:

Versatility

Multi-material fasteners are designed to work with different materials, including concrete, wood, metal, and more. This versatility allows you to use the same fastener for various applications, saving you time and effort in finding specific fasteners for different materials.

Ease of installation

SPAX® multi-material fasteners are heat treated to a grade 5 durability which provides a tuff surface to the patented thread serrations. SPAX screws can tap their own thread hole in concrete once the proper pilot hole is established which in turn provides a great hold strength for side member attachment. This simplifies the installation process and reduces the risk of damaging the concrete surface.

Enhanced holding strength

Multi-material fasteners are often designed to provide strong and durable connections between different materials. They are engineered to create a reliable bond or grip that can withstand the weight and forces exerted on the furring strips over time.

Aesthetics

Certain multi-material fasteners can be installed in a way that minimizes their visibility.

Adjustable positioning

In some cases, multi-material fasteners allow for adjustment or repositioning of the furring strips after installation. This flexibility can be beneficial if you need to make minor adjustments or modifications during the installation process.

Multi-Material Flat Head Construction Fasteners

German engineered and American made, SPAX® Multi-Material Engineered Construction Fasteners are professional grade and designed to make strong connections - the first time.

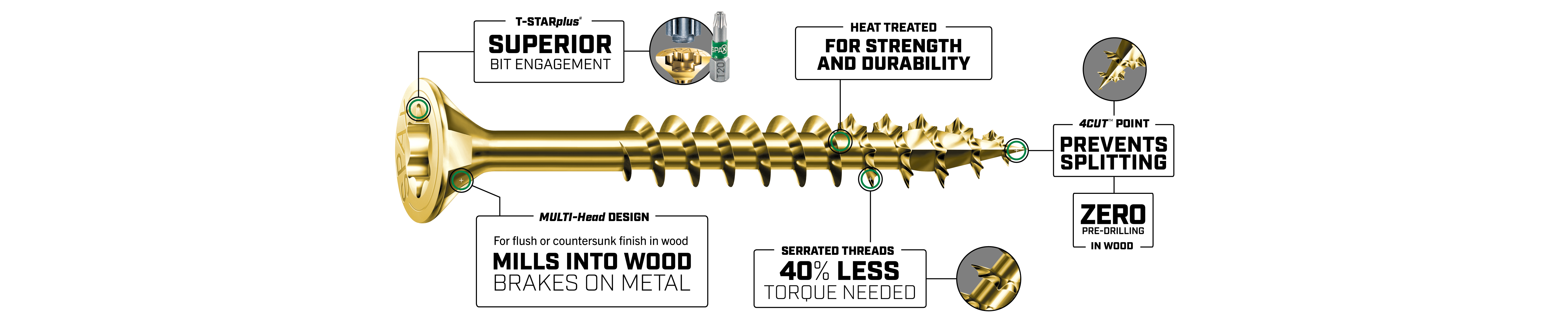

T-STARplus® Drive

"The PRO's Choice" drive system provides superior bit engagement, eliminates camming out and facilitates overhead driving.

MULTI-Head Design

Countersinks screw head flush with material.

Serrated Threads

Allow for quicker, easier fastening.

Unique 4CUT™ Point

Prevents splitting and requires no pre-drilling in wood.

SPAX is Independently Tested and Approved

Residential