Conduit Installation: Plan Conduit Strap Placement in Advance

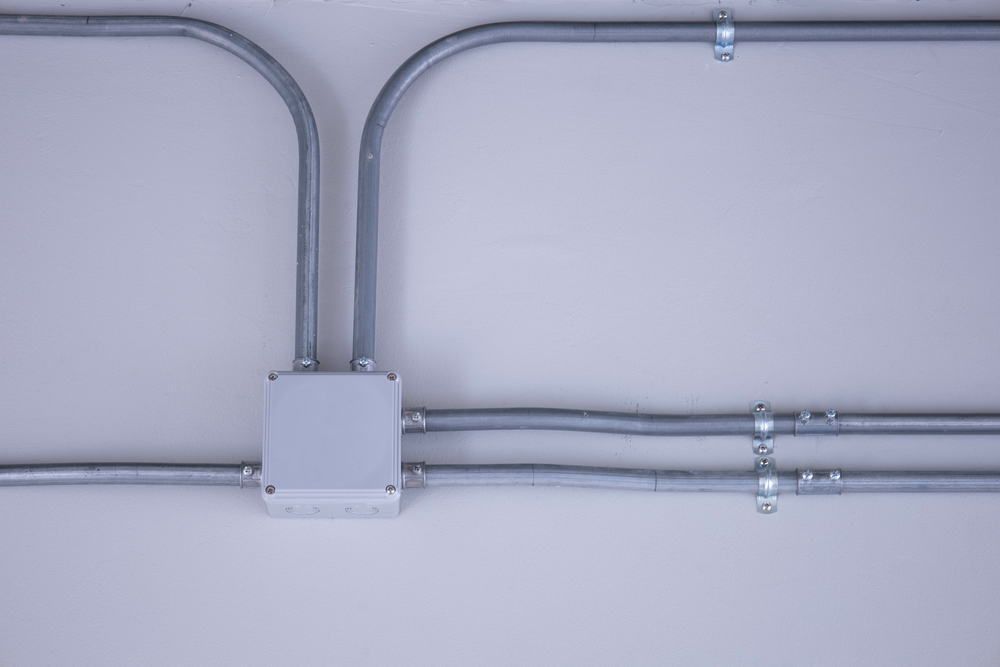

We recommend planning strap placement in advance for the simple fact that straps must be placed in accordance with building codes and industry standards. Straps can affect an entire conduit installation profoundly. So not thinking about placement ahead of time could create frustrating problems later on.

Part of the planning for strap placement is choosing the right fasteners. SPAX all-purpose fasteners are ideal for conduit strap jobs, even when fastening straps to masonry. All you need are your straps, our multi-purpose fasteners, the correct bit, and a power driver.

Placement Locations Matter

To the untrained eye, it might seem that contractors can place conduit straps wherever they feel like it. The only requirement is to make sure the conduit is properly supported, right? No. Experienced electrical contractors know it is not that simple.

Different types of conduit must adhere to slightly different standards. Electricians need to know this. As an example, NEC standards relating to conduit strap placement for PVC conduit are as follows:

A strap must be placed within 3 feet of any outlet, panel, disconnect, or other juncture.

The distance between conduit strap should be no more than 10 feet along the length of a run.

A strap should be placed on either side of every box or junction.

A strap should be placed on either side of every bend (including elbows).

Every offset should be preceded by one strap immediately before it.

These standards are just the starting point. Local and state codes may include additional standards electrical contractors are expected to follow. Here's the point: smart contractors plan for strap placement when developing an overall conduit installation plan.

Failing to plan for strap placement could mean finding yourself in a position of having run conduit in such a way as to prevent proper strap placement. In such a case, what you have already run has to be removed and run again to accommodate straps in a compliant way.

Save Time with SPAX

Running conduit isn't necessarily a complicated job. However, it is time-consuming. Proper planning can reduce the amount of time spent on actual installation by accounting for any special circumstances that would otherwise create problems.

Contractors can also save time by choosing the right materials. That is where SPAX comes in. Not only are our conduit strap fasteners engineered to be strong, durable, and code compliant, but they are also designed for fast and efficient installation.

If you are installing straps on lumber, no pre-drilling is necessary. Just drive and go. That is one of the advantages of choosing SPAX engineered fasteners. When installing in masonry, drilling pilot holes will make installation easier. A pilot hole sized appropriately to the fastener will ensure quick and efficient work when the time comes.

Don't Go in Without a Plan

SPAX engineered fasteners were not designed haphazardly. We didn't go into this with the thought of throwing things against the wall to see what would stick. Rather, a lot of time and planning went into our engineering. We still put the same amount of time and effort into making SPAX fasteners better.

We encourage you to do likewise. Don't go into conduit installation without a plan. Plan everything from conduit routes to strap placement and the materials you will utilize. With a sound plan in place, you will do the job faster and more efficiently.

Related Products