The SPAX® difference

What makes SPAX engineered fasteners different than other fastener products?

Strength and job site efficiency innovations such as our patented 4CUT™ point, serrated threads, HCR-X™ coating for advanced corrosion resistance, ZERO pre-drilling and comprehensive product testing means SPAX Engineered Fasteners are the most advanced fastener product on the market, providing the power to keep your projects connected stronger for longer.

What makes the T-STAR plus so different?

T-STAR plus is the latest evolution in fastener recess design. Our proprietary design virtually eliminates all bit wobble and reduces recess stripping. Our design offers a tight secure fit allowing the bit to grip the screw freeing the user's opposite hand to hold the workpiece and drive the screw in awkward positions.

What makes the 4CUT so different?

The SPAX 4CUT was born from decades of experience and research in fastener design. Our patented designs symbolize the latest technology in wood fastener design. The proprietary 4CUT tip offers unrivaled performance in reducing wood splitting while retaining maximum thread withdrawal performance. In head-to-head testing, the SPAX 4CUT tip outperforms Type 17 and others in start time and wood-splitting prevention. The arrow-shaped CUT tip in combination with the wave profile reduces the splicing and tearing of the wood. In addition, the CUT tip enables the screw tip to be applied very precisely and without slipping, even on smooth surfaces.

What makes the Multi-Head so different?

The SPAX Multi-Head was born from decades of experience and research in fastener design. Our patented designs symbolize the latest technology in wood fastener design. The Multi-Head mills a depression into the wood with its polygonal underside ("pockets") and can therefore be countersunk without additional countersinking of the screw hole. The countersunk head is flush with the surface. Additionally, the polygonal underside, or "pockets" create an automatic brake to the screw when the screw hits a metal surface, like a bracket, connector, or hinge, preventing the screw from stripping out the wood pocket.

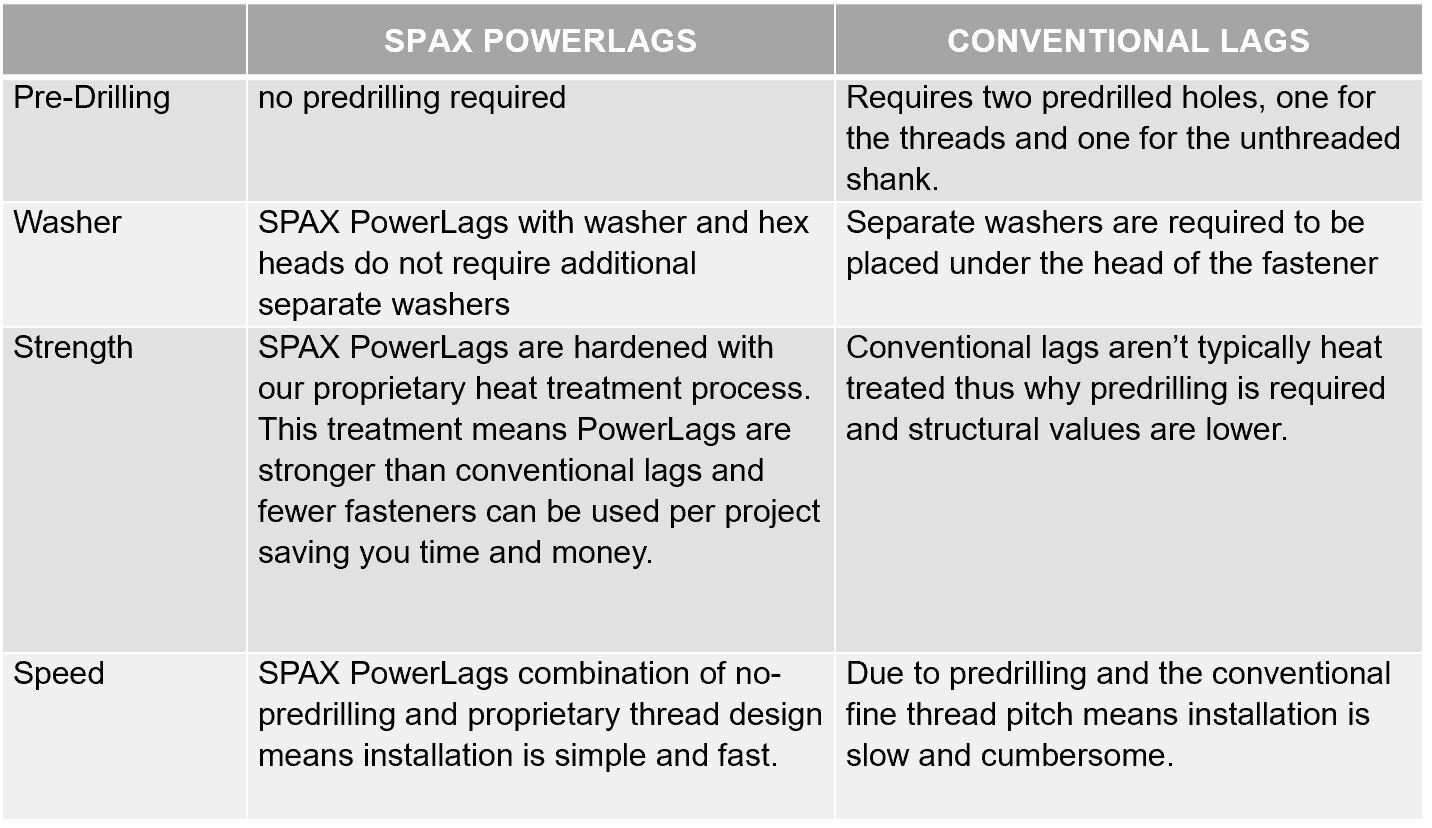

What makes the SPAX PowerLag better than the Conventional Lag?

Purchasing

where are spax® fasteners available?

SPAX® fasteners are available nationwide at most local home improvement retailers, lumberyards and industrial supply houses, and online outlets across the U.S.

How many fasteners do I need?

Deck Board Installation: Reference our decking fastener calculator

Deck ledger: Reference SPAX Deck Ledger Technical Bulletin

Multi-ply assembly: Reference SPAX Multi-Ply Technical Bulletin

Truss/Rafter connection: Reference SPAX Truss/Rafter to Top Plate Connection Technical Bulletin

For all other applications, we recommend referencing your local building code for guidance.

Product Terminology

why do you call your fasteners “multi-material”?

The SPAX® Multi-Material fasteners crafted with our proprietary design and patented features allow them to perform in a wide variety of applications and materials other than wood, including concrete, masonry, light gauge sheet metal (24 ga.), and plastics.

WHAT DOES T-STAR PLUS MEAN?

T-STAR plus is the latest evolution in fastener recess design. Our proprietary design virtually eliminates all bit wobble and reduces recess strippage. Our design offers a tight secure fit allowing the bit to grip the screw freeing the users opposite hand to hold the work piece and drive the screw in awkward positions.

WHAT DOES TORX, HEXLOBE AND T-STAR DRIVE MEAN?

Torx, Hexlobe and T-STAR are various names used to describe the standard 6-lobe recess found in wood screws. A popular generic name for the drive is star, as in star screwdriver or star bits.

WHAT DOES UNIDRIVE MEAN?

Unidrive is a Phillips/Square Drive combo system. This unique drive gives users the option of using either a Phillips or a Square drive bit to install the SPAX® fastener. Our proprietary Unidrive bit is specifically designed to maximize the bit contact surface area giving the best performance and experience.

WHAT is the SPAX 4CUT?

The Spax 4CUT was born from decades of experience and research in fastener design. Our patented designs symbolize the latest technology in wood fastener design. The proprietary 4CUT tip offers unrivaled performance in reducing wood splitting while retaining maximum thread withdrawal performance. In head to head testing, the SPAX 4cut tip outperforms Type 17 and others in start time and wood splitting prevention.

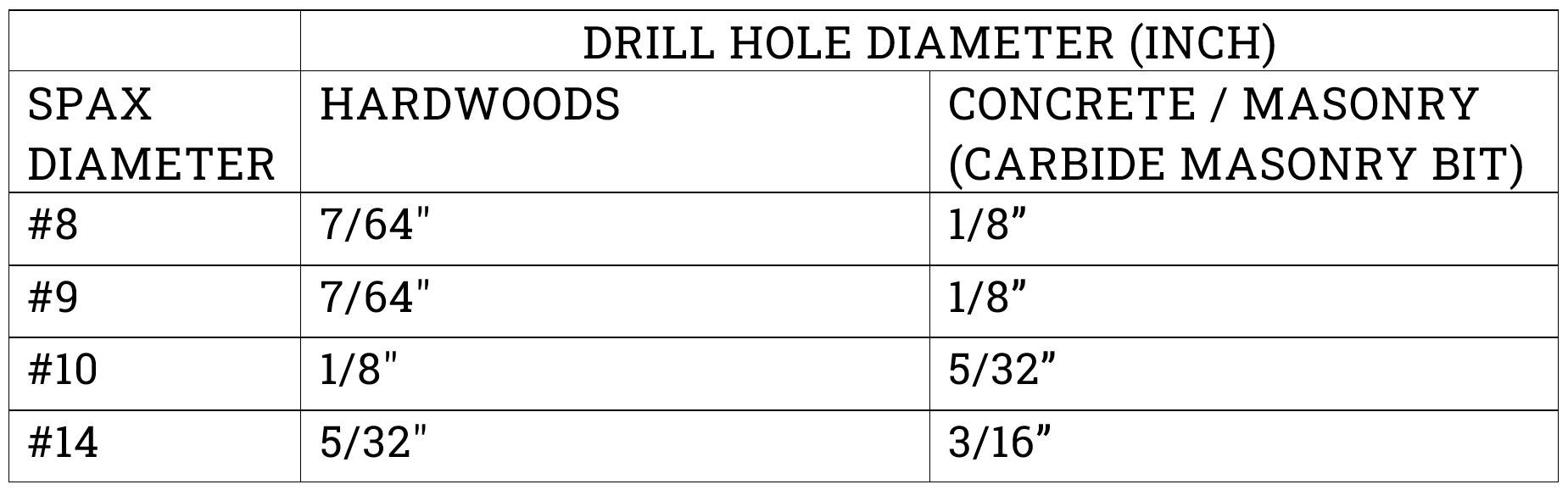

Your packaging says "no pre-drilling". Does this include concrete?

No, pre-drilling is referencing application with softwoods— not concrete. Concrete applications require pre-drilling with a carbide masonry drill bit before installing the SPAX® fastener. The required hole size is published on the back of our Multi-Material product packaging.

PRE-DRILL RECOMMENDATIONS FOR HARDWOODS AND CONCRETE / MASONRY

WHAT IS GALVANIC CORROSION?

Also called dissimilar metal corrosion, galvanic corrosion refers to an electrochemical process when two dissimilar metals come into contact in the presence of an electrolyte. The most common electrolyte for wood screws is water. To avoid galvanic corrosion, use materials made from the same metal. When dissimilar metals must be used, consider introducing a barrier between the dissimilar metals such as a rubber washer or polymer bushing to minimize corrosion.

WHAT IS CASE HARDENING?

Case-hardening is the process of hardening the surface of a fastener while allowing the metal underneath to remain soft and ductile. This allows the fastener to be strong but durable at the same time.

Application & Proper Use

CAN I USE SPAX FASTENERS IN TREATED LUMBER?

Yes! Our Multi-Material construction screws with HCR-X™ coating, PowerLags® with high corrosion resistant (HCR®) coatings, and 304 Stainless Construction and PowerDeck screws are approved for use in treated lumber.

CAN I USE SPAX FASTENERS WITH CEDAR AND REDWOODS TO PREVENT TANNIN STAINING?

Yes! Stainless steel is recommended for cedar and redwoods to prevent staining from the natural oils (tannins) in the wood.

CAN I USE SPAX FASTENERS NEAR COASTAL SALT WATER?

Yes! For coastal exterior applications, SPAX recommends the use of 304 or 316 series stainless steel within 5 miles of coastal salt water.

DO SPAX® ENGINEERED FASTENERS REQUIRE PRE-DRILLING FOR ICC AND DRJ CODE COMPLIANCE?

No. Unlike traditional lags, SPAX PowerLags® are IRC/IBC code compliant and DrJ code-compliant for deck ledger attachment multi-ply applications and do not require pre-drilling for full strength ratings, offering dramatically increased installation speed across your projects.

YOUR PACKAGING SAYS “NO PRE-DRILLING.” DOES THAT INCLUDE CONCRETE?

No pre-drilling is referencing application with hardwoods — not concrete. Concrete applications require pre-drilling with a carbide bit before installing the SPAX® fastener. Required hole size is published on the back of our product packaging.

ARE THERE ANY TIPS FOR USING SPAX® FASTENERS IN CONCRETE?

Yes. Be sure to use the correct diameter fastener for the application and predrill a hole using the appropriate carbide masonry drill bit found on the back of Multi-Material fastener packaging. Embedment into the masonry should be 1” min. to 1-1/2” max. Also, pre-drill the hole ¼” deeper than the thread engagement to prevent the fastener from bottoming out. Be sure to clear the hole of debris before installing the fastener.

WHY CAN’T I USE POWERLAGS® IN CONCRETE?

The PowerLags® thread pitch and threads-per-inch design is different than our multi-purpose fasteners. PowerLags are designed to be high-performance fasteners for wood-to-wood applications only.

Can i install drywall with SPAX Multi-Material Construction Screws?

Yes, hanging drywall is a perfect application for SPAX Multi-Material Construction screws.

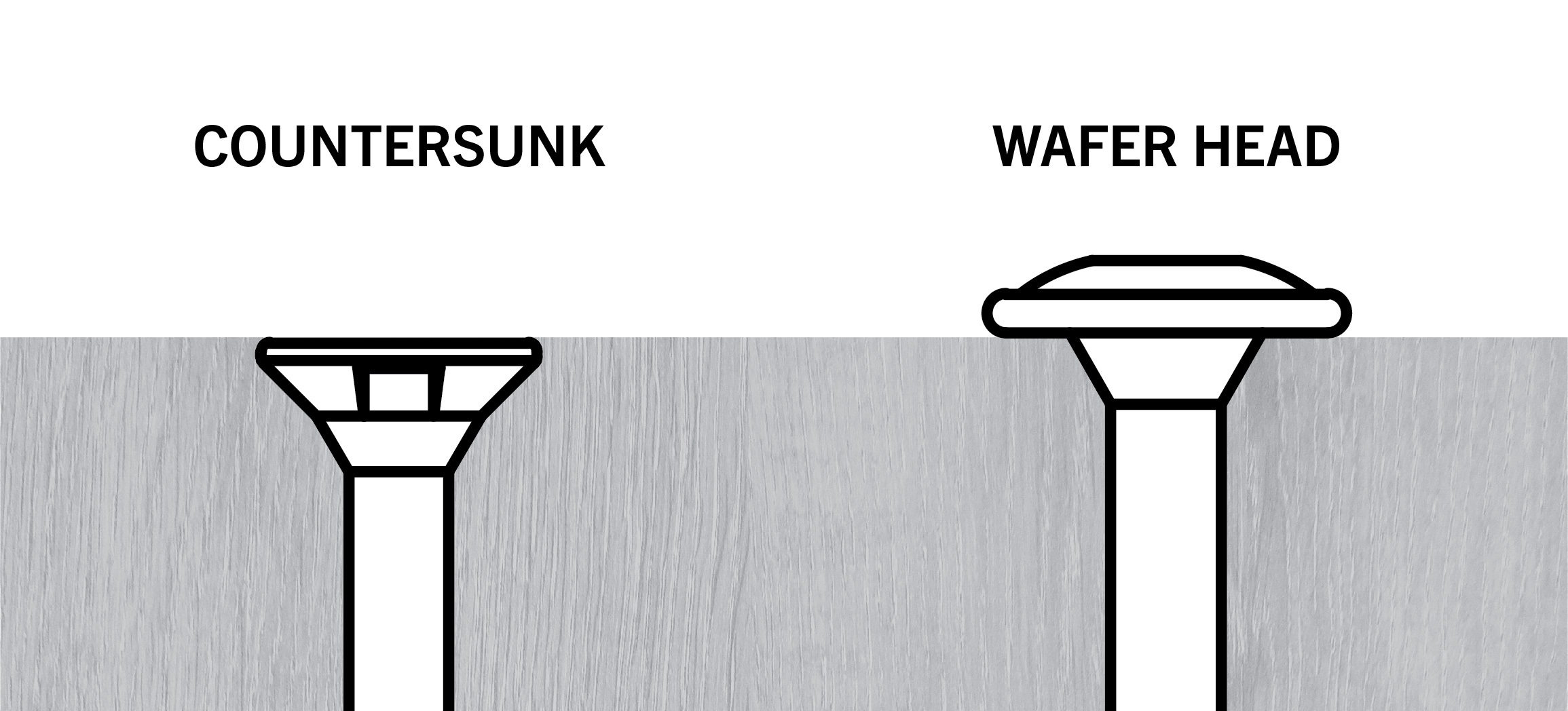

Are SPAX screws self-countersinking?

SPAX patented countersunk multi-head screws are designed to be self-countersinking. Wafer head screws are designed to seat flush with the underside of the head. Overdriving wafer head screws will compromise the published allowable strength loads.

WHAT IS THE DIFFERENCE BETWEEN ULTIMATE AND ALLOWABLE LOADS?

Ultimate values are the average values a fastener breaks/fails in laboratory tests.

Allowable values are Ultimate values with an industry-accepted safety factor applied.

WHAT IS THE STRENGTH OF MY CONNECTION?

The strength of a connection rarely depends on the strength properties of the screw. The wood will often fail before the screw. The strength of the connection depends upon the size and species of wood. See our listed ICC-ES and DrJ Engineering Reports for values with specific assemblies.

CAN I USE STANDARD TORX BITS WITH T-STAR PLUS?

To take advantage of our superior bit fit we recommend using our T-STAR plus bits. However, our recess design also allows the use of standard T-STAR and Torx driver bits for added versatility.

material & Coating

WHAT EXACTLY IS HCR®?

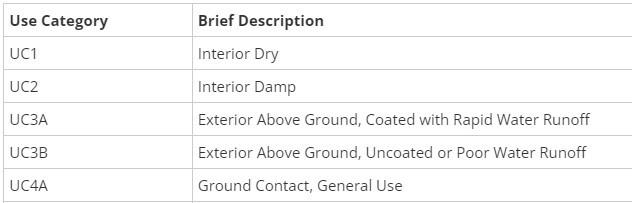

HCR® (High Corrosion Resistant) is a dual barrier coating system designed specifically for SPAX PowerLags that maximizes corrosion resistance while providing lasting strength in treated lumber applications. SPAX HCR has been independently tested according to ASTM B117 testing methodology and carries ICC-ES AC257 Treated Lumber approval. SPAX HCR is approved for use in untreated wood above and ground contact pressure-treated wood for exterior, freshwater, and general construction applications (American Wood Protection Association UC1- UC4A).

WHAT IS HCR-X™?

HCR-X™ (Extra High Corrosion Resistance) is our latest proprietary dual barrier coating system developed by SPAX® for our Multi-Material Construction and Deck screws. SPAX HCR-X has been independently tested according to ASTM B117 testing methodology and carries ICC-ES AC257 Treated Lumber approval. SPAX HCR-X is approved for use in untreated wood, above and ground contact pressure treated wood for exterior, freshwater, general construction applications (American Wood Protection Association UC1- UC4A).

IS SPAX HCR & HCR-X COATINGS APPROVED FOR GROUND CONTACT?

Yes, HCR and HCR-X are both approved for AWPA UC4A, ground contact, general use. Please reference AWPA guidelines for further information regarding AWPA use conditions.

WHAT IS ZINC (SILVER) AND YELLOW ZINC COATING?

Our zinc and yellow zinc coatings are designed specifically for interior construction applications. While basic, these coatings have also been independently tested and approved for interior dry and damp conditions (AWPA UC1-UC2).

WHAT IS THE DIFFERENCE BETWEEN BLUE ZINC (SILVER) AND YELLOW ZINC?

The first difference is the color itself, which gives the user an option for aesthetics. The yellow zinc is a slightly higher grade of plating for corrosion protection vs. the blue zinc.

WHAT ARE SPAX® SCREWS MADE OF?

SPAX® fasteners start their life with the best fine grain carbon steel we can find, are cold formed into shape, and then heat treated using our proprietary, state-of-the-art heat treat process. What this means to you is that you are using the toughest, most durable fasteners made in the world. Our in-house process guarantees unmatched consistency that you can count on. Excluding our 304 series stainless steel line, all of the SPAX® fasteners are heat treated to Grade 5 durability carbon steel, from the small #6 diameter fasteners up to the ½” diameter PowerLags®.

CAN I USE SPAX FASTENERS IN TREATED LUMBER?

Yes! Our Multi-Material construction screws with HCR-X™ coating, PowerLags® with high corrosion resistant (HCR®) coatings, and 304 Stainless Construction and PowerDeck screws are approved for use in treated lumber.

CAN I USE SPAX FASTENERS WITH CEDAR AND REDWOODS TO PREVENT TANNIN STAINING?

Yes! Stainless steel is recommended for cedar and redwoods to prevent staining from the natural oils (tannins) in the wood.

CAN I USE SPAX FASTENERS NEAR COASTAL SALT WATER?

Yes! For coastal exterior applications, SPAX recommends the use of 304 or 316 series stainless steel within 5 miles of coastal salt water.

WHAT IS CASE HARDENING?

Case-hardening is the process of hardening the surface of a fastener while allowing the metal underneath to remain soft and ductile. This allows the fastener to be strong but durable at the same time.