Shed Screws and Fasteners

SPAX® offers the right assortment of fasteners to build strong, long-lasting sheds and small buildings to enhance your structure's structural integrity and longevity. This guide will help you take into consideration the type of screws, coatings, sizes, and whether they are appropriate for the materials you're joining.

Master Your Projects with Confidence

Building a Shed or Outbuilding

Sheds and tiny buildings are a fast-growing segment among homeowners, creating high demand for a variety of different fasteners as manufacturers and contractors move from traditional nails and screws. SPAX® offers a wide range of high-performance fasteners, making them the ideal partner for manufacturers and contractors looking for strength, versatility, and efficiency in every build.

Fasteners for Shed Building

The lineup SPAX® offers of PowerLags in both hex and washer style heads gives the contractor many options to fit several applications on a job. SPAX® offers lags from ¼" to ½" in diameter up to 12" lengths in certain diameters. With the broadest range of lengths and diameters in the market, SPAX® provides solutions for flooring, beams, truss systems, and much more.

Some end users are are looking for other options when it comes to nails and hurricane clips. One of those options is the SPAX® truss rafter screw. Offered in #14 x 6 ¼", it makes for the perfect fastener for the small truss systems inside of a shed.

SPAX® also offers a multi-material screw in both a flat counter sunk head as well as a low-profile wafer head. These are offered in both interior and exterior coatings. With a large range of diameters and lengths offered, SPAX® has great solutions for framing, subfloor, decorative attachments, composite flooring, and many other applications.

Most of SPAX® products are available in bulk options which makes it attractive for contractors and manufacturers producing these structures in high volume.

We’ve Got You Covered

Find the right screw or fastener for your next job with the largest variety of diameters, lengths and head styles in the industry.

Related Products

Versatile Screws for Every Stage of Your Project

It's essential to choose screws with appropriate length, diameter, and thread pattern to match the specific applications and material thickness. Additionally, selecting screws with corrosion-resistant coatings or materials ensures durability, especially for outdoor shed construction.

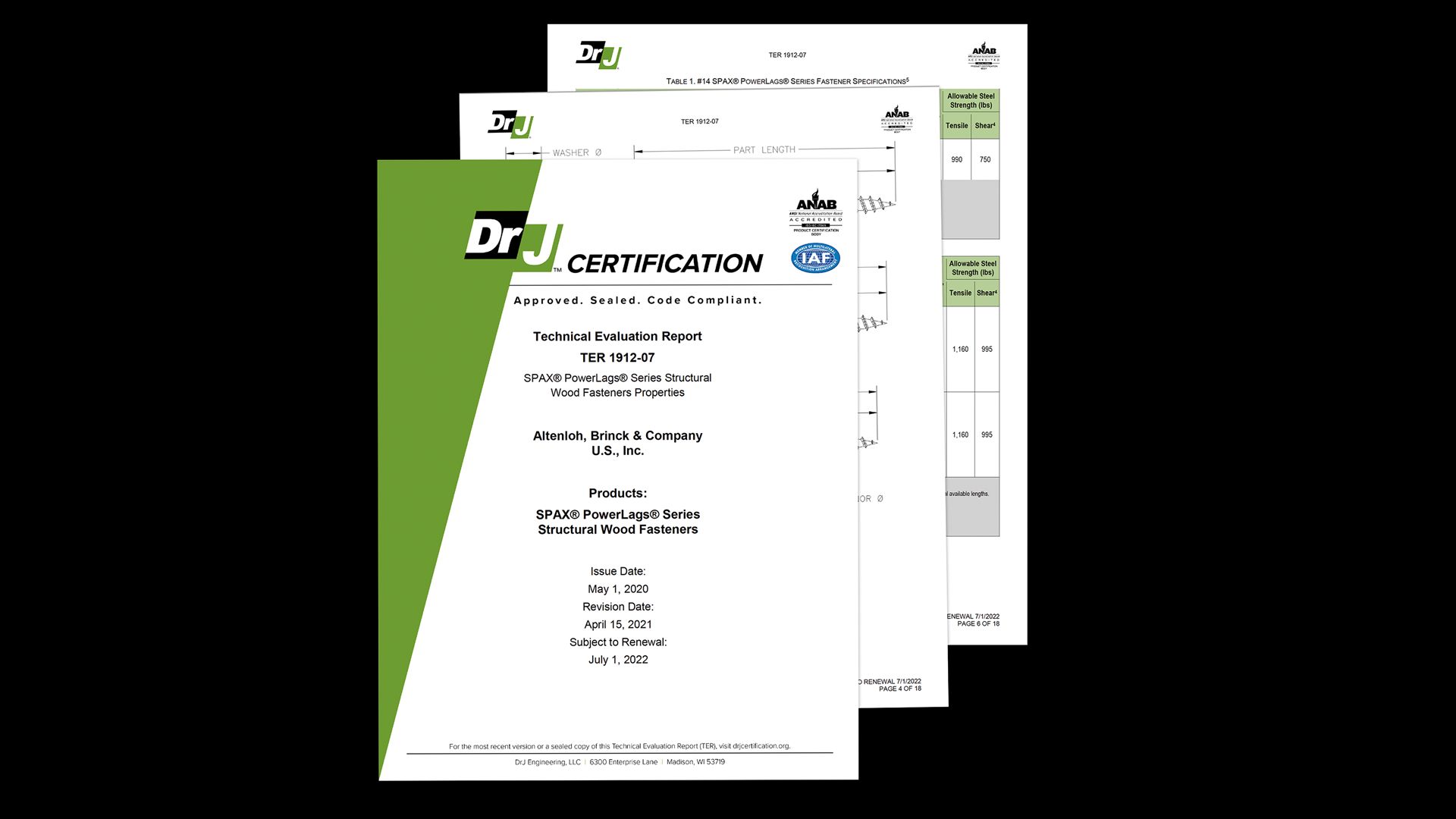

SPAX® POWERLAGS® HIGH PERFORMANCE

SPAX offer the largest selection of code-recognized structural wood-to-wood fasteners in the industry.

SMART ALTERNATIVE FOR THE CONVENTIONAL LAG

High Performance. High Value.

The largest selection of code-recognized structural wood-to-wood fasteners in the industry!